Commercial Window Tinting in Bend, Oregon — Expert Solutions for Businesses

Commercial window tinting is an architectural retrofit that uses specialty films to cut solar heat gain, block harmful UV, improve occupant comfort, and boost privacy for businesses in Bend. This guide walks through how commercial window film works, the measurable benefits for Central Oregon facilities, the film types that perform best here, common commercial uses, and the practical steps for a smooth installation. Business owners, property managers, and facilities teams will get clear guidance on energy and glare reduction, security and decorative options, and how to evaluate ROI and product performance using standard metrics like VLT, SHGC, and percent UV block. We also cover Bend-specific factors — seasonal sun angles and wide daytime temperature swings — and how they affect film choice and projected savings. Finally, you’ll find an installation checklist, cost and maintenance answers, and tips to compare options and plan projects with confidence.

Key Benefits of Commercial Window Tinting for Bend Businesses

Commercial window film reduces solar heat gain by reflecting and absorbing infrared and visible light, helping protect interiors and easing HVAC load. Films typically combine metalized or ceramic layers with an adhesive and a UV-blocking coating to reject solar energy while preserving desired daylight. The practical results for Bend businesses include lower cooling costs, less interior fading, steadier indoor temperatures, reduced screen glare, and improved privacy or branded storefront treatments. In a climate with strong sun and notable diurnal swings, these benefits translate into more consistent comfort and measurable operational savings.

In straightforward terms, commercial window tinting delivers several measurable outcomes:

Reduced energy use and HVAC load through lower solar heat gain.

High UV protection to preserve finishes and merchandise.

Less glare for better employee productivity and customer experience.

Privacy and visual upgrades that support branding and space planning.

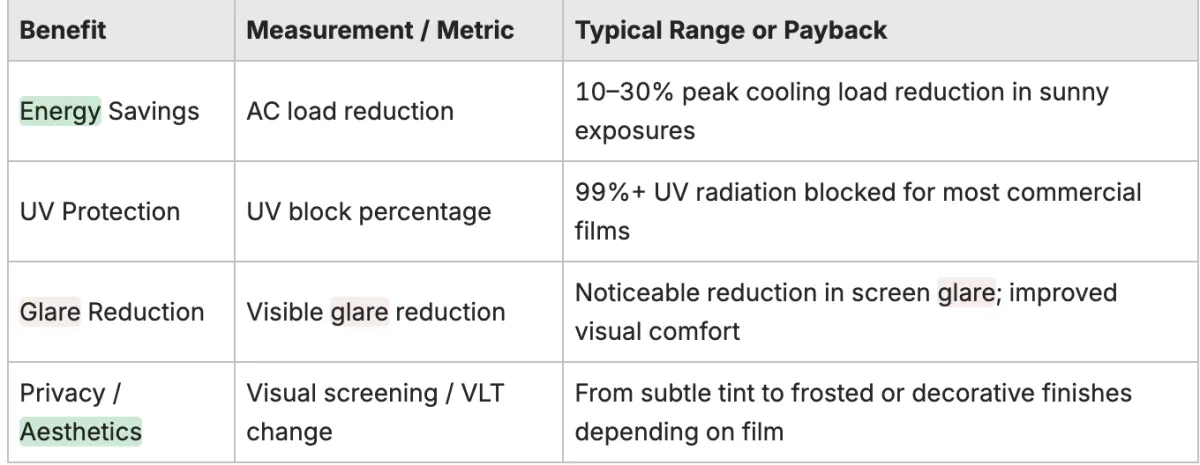

The table below summarizes common ROI-focused benefit metrics for commercial films and helps set realistic project expectations.

Use these metrics to shape conversations with installers and to set realistic payback timelines for your project.

If you want local installation and a site assessment, Alpha Shielding LLC offers commercial window film services tailored to Central Oregon — contact us by phone for quotes and consultations.

How Window Film Improves Energy Efficiency and Cuts Costs

Solar control films improve energy efficiency by reflecting and absorbing incoming solar energy before it becomes internal heat, which lowers cooling demand. Different technologies — metalized layers for reflectivity or multi-layer ceramic formulations that selectively block infrared — target heat while keeping visible light. Lowering the Solar Heat Gain Coefficient (SHGC) reduces peak cooling loads and can result in monthly energy savings for conditioned spaces. Buildings with large west- or south-facing glazing typically see the biggest HVAC reductions and the quickest payback when cooling use is significant.

Facility teams should evaluate films using VLT (Visible Light Transmission), SHGC, and IR-rejection specs to balance daylighting with heat control. Picking the right film for each orientation and glass type lets you keep useful daylight while reducing reliance on mechanical cooling — a practical approach that leads into the next section on film categories and their intended outcomes.

How Window Tinting Enhances Privacy, Security, and Comfort

Privacy and security films change sightlines and add a protective layer that helps keep glass intact on impact, improving safety without full-glass replacement. Privacy options include one-way reflective films, frosted finishes, and printed graphics that combine screening with brand messaging. Security or safety films are thicker laminates that hold glass fragments together during breakage, slowing forced entry and reducing injury risk. Comfort benefits include lower radiative heat transfer and reduced glare, which help stabilize interior temperatures and support a more productive environment for staff and visitors.

When specifying privacy or security films, consider VLT, film thickness (mil rating), and warranty terms to match your risk profile and aesthetic goals. Many projects use a hybrid approach — decorative or privacy film at street level and solar-control films above — to balance daylight, protection, and curb appeal. These choices are part of the broader selection of films suitable for Bend businesses, covered in the next section.

Which Types of Commercial Window Films Work Best for Bend Businesses?

Commercial films generally fall into solar control, security/safety, decorative/privacy, and smart/switchable categories — each built from layers such as metalized coatings, ceramic elements, UV-blocking films, and adhesives. Solar-control films prioritize IR and near-IR rejection and are specified using SHGC and VLT to find the right balance of daylight and heat rejection. Security films vary by thickness for impact resistance and shatter retention. Decorative films support branding and privacy while offering cleanable surfaces for healthcare and food-retail environments.

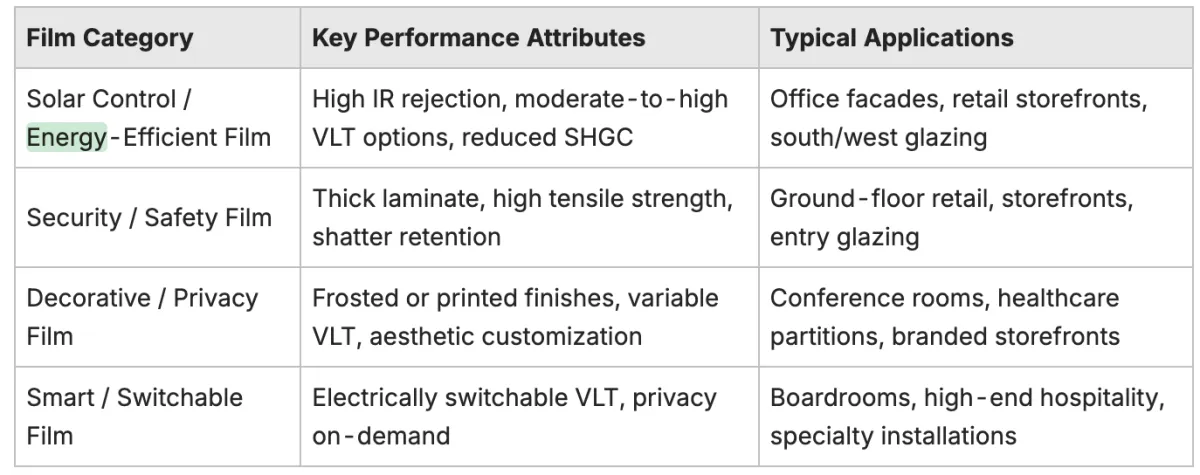

The comparison below helps match film categories to performance traits and common applications.

Alpha Shielding LLC partners with commercial-grade solar and safety film manufacturers and can advise on trade-offs between visible light and heat rejection. Our local experience helps match film choices to Bend’s seasonal sun patterns and building orientations.

Understanding film categories and their technical strengths is the first step toward selecting products that deliver the outcomes you need in Central Oregon.

Features of Solar Control and Energy-Efficient Films

Solar-control films combine metalized or ceramic coatings, UV-blocking layers, and scratch-resistant topcoats to selectively reject solar energy while preserving daylight. Key specs to compare are VLT, SHGC, and IR-rejection percentage — together they show how much light, heat, and infrared a film rejects. Ceramic films are non-metallic, keep color stable, and cause less signal interference; metalized films often give higher reflectivity and heat rejection but can increase exterior reflectivity. The right balance depends on window orientation, occupant needs, and energy goals.

Knowing these features helps facility managers choose films that keep comfortable daylight in occupied spaces while cutting mechanical cooling demand. The next section reviews trade-offs when security and privacy are primary concerns.

How Security and Privacy Films Protect Commercial Properties

Security films bond to glass with high-strength adhesive to hold fragments together during breakage, delaying forced entry and reducing injury from shattered glass. Thickness (measured in mils) correlates with tear resistance and forced-entry delay, though thicker films may be more noticeable on the glazing. Privacy films include one-way reflective options that preserve outward views, frosted films for diffused light, and printed/graphic films for branding. Installations range from single-pane retrofits to laminated assemblies for higher-risk locations.

Choosing the right security or privacy film requires balancing visual expectations, regulatory needs, and functional outcomes like safety and brand visibility. Facility teams should match film grade to security protocols and privacy requirements before procurement and installation.

Common Commercial Window Tinting Applications in Bend, Oregon

Commercial film is used across offices, retail storefronts, healthcare, education, hospitality, and municipal buildings — each use case targets different benefits such as glare control, merchandise protection, patient privacy, or aesthetic upgrades. Offices typically prioritize glare reduction and thermal comfort to support productivity; retail focuses on fade protection and customer comfort to boost sales conversions. Healthcare and education settings value privacy, cleanable surfaces, and calming appearances, often choosing frosted or antimicrobial-capable films. Municipal and hospitality projects frequently combine solar control with security films for safety and guest comfort.

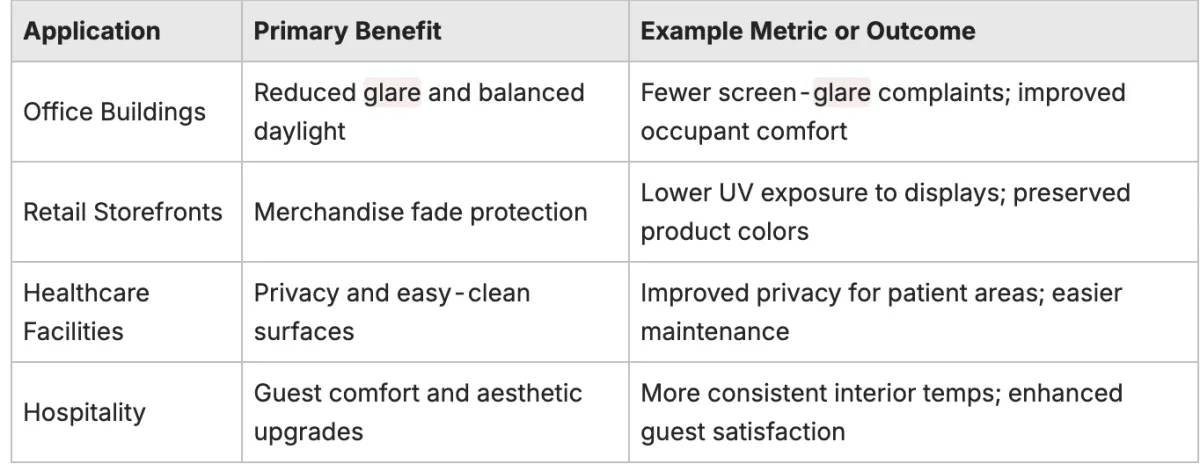

The table below links common applications to measurable benefits and local outcomes for project scoping and ROI planning.

Successful projects align film attributes with building goals and Bend’s local climate patterns.

Benefits for Office Buildings and Workspaces

In offices, film reduces screen glare, evens temperatures near windows, and balances daylight to improve comfort and productivity. Films with moderate VLT preserve natural light while cutting reflections on monitors and conference screens. Energy-efficient films on south- and west-facing facades smooth peak cooling loads and reduce temperature stratification near glazing, improving overall HVAC performance. Decorative films can add privacy to meeting rooms without blocking daylight, keeping spaces open yet confidential.

These practical improvements make window film a cost-effective retrofit. The following sections cover retail and healthcare cases where protection and privacy are primary drivers.

Why Retail Storefronts and Healthcare Facilities Choose Window Film

Retailers use film to guard merchandise against UV fade, reduce solar heat near displays, and keep customers comfortable. Healthcare facilities choose films for privacy, cleanability, and calming aesthetics. For example, retail spaces may see less color fade on textiles and longer customer dwell times due to improved comfort, while clinics use frosted or patterned films to protect patient privacy and simplify cleaning. Recommended films vary by use: solar-control films with strong UV block for retail displays, and washable frosted or antimicrobial-compatible films for healthcare partitions.

Matching film selection to application ensures measurable benefits and a better experience for occupants and customers.

Why Choose Alpha Shielding LLC for Commercial Window Tinting in Bend?

Alpha Shielding LLC is a Central Oregon company offering automotive detailing, ceramic coatings, paint protection film, and commercial window tinting. We bring hands-on experience with film materials and installation techniques. Our local knowledge of Bend’s sun angles and seasonal temperature swings helps us recommend products that fit building orientation and business goals. The company lists over 20 years of experience and a 4.9-star rating from 37 Google reviews as of April 2024 — indicators of consistent, local workmanship.

Our local presence and integrated service model make project coordination easier: on-site assessments, product selection guidance, and scheduling that works around your operation. For businesses wanting a local installer, give Alpha Shielding LLC a call to connect with a team experienced in Central Oregon commercial installs.

Alpha Shielding’s Experience and Project Expertise

Alpha Shielding’s services include professional window tinting alongside other protective films, and our local credibility is reflected in a 4.9-star aggregated review score from 37 Google reviews as of April 2024. That mix of practical film work and positive feedback shows hands-on knowledge in surface prep, film handling, and installation techniques critical to commercial glazing projects. Skills developed in automotive and protective-film work — careful prep, precise cutting, and attention to finish — translate directly to architectural installations where fit, edge sealing, and longevity matter.

When evaluating installers, look for teams who can explain performance metrics and show real-world installations; our local track record helps bridge manufacturer specs with Bend-specific installation practice to reduce performance surprises.

How Premium Products and Local Service Improve Your Experience

Premium commercial films offer scratch-resistant topcoats, reliable UV protection, and consistent optical clarity that preserves views. Combined with local service and timely maintenance, these films deliver predictable long-term performance and quicker response if adjustments are needed. Installers who understand Central Oregon climates can recommend films that retain color and adhesion through temperature swings and provide realistic warranty expectations tied to local conditions.

Working with a nearby installer also simplifies site surveys, follow-up checks, and warranty service, giving facility managers faster response and smoother project coordination. Those product-and-service synergies help lower lifecycle costs and support long-term performance for commercial properties.

Our Commercial Window Tinting Installation Process

We follow a clear workflow: consultation and site survey, product selection and quote, precise measurement and scheduling, the installation itself (cleaning, film application, trimming, and curing), and a final inspection with maintenance guidance. Each phase has specific tasks: the site survey documents glazing and exposures; product selection aligns film specs with goals; installation follows manufacturer protocols for adhesion and edge sealing; and final QA verifies optical clarity and performance. We prioritize transparent timelines and minimizing business disruption, and can schedule work during off-hours when needed.

Below is the typical sequence businesses can expect during a commercial window film project.

Site Survey and Consultation: Document glazing types, exposures, and performance goals for accurate specification.

Film Selection and Quoting: Match film attributes to goals and provide itemized estimates for materials and labor.

Scheduling and Prep: Coordinate install windows to minimize business disruption and prepare work areas.

Film Application and Curing: Clean substrates, apply film precisely, trim edges, and allow proper curing time.

Final Inspection and Handover: Verify optical quality, review maintenance requirements, and document warranty information.

This phased approach sets clear expectations and reduces the risk of surprises during installation. The next section outlines prep steps businesses can take before installers arrive.

Step-by-Step Phases of Commercial Window Film Installation

Installation starts with a thorough site survey and continues through careful substrate cleaning, precise patterning and wet application, squeegee-driven adhesion and edge trimming, and final inspection for optical defects and proper sealing. Installers follow manufacturer guidelines: surfaces must be free of contaminants for adhesion, and films require specified drying or curing times to avoid edge lift. When scheduled properly, install-day impacts are minimal, though some areas may need brief access restrictions or short periods of noise from trimming tools.

Clients should expect documented glazing assessments and timeline estimates; larger jobs are commonly staged to keep business operations running. Correct sequencing and quality checks are essential to long film life and warranty compliance.

How to Prepare Your Building for a Tinting Project

Preparation speeds installation and reduces downtime: clear furniture near windows, remove wall-mounted items or window treatments, notify staff and customers of scheduled work, and plan temporary restricted-access zones if needed. Facility managers should verify any permitting requirements and ensure decision-makers are available for final film approvals. Communicate building access, power availability, and after-hours needs with the installation team to avoid delays and minimize disruption.

Use this short checklist to coordinate with installers and keep operations running smoothly during the project:

Clear furniture and obstructions within a few feet of glazing.

Remove or secure suspended items and blinds where applicable.

Provide a point-of-contact for installers and confirm access arrangements.

Schedule work during low-traffic hours to reduce customer impact.

These steps streamline installation and help ensure a safe, efficient job.

Frequently Asked Questions

What Factors Should Businesses Consider When Choosing Window Film?

Choose film based on performance attributes, local climate, and intended application. Key specs include VLT, SHGC, and UV-block percentage to evaluate heat and glare control. Also consider appearance, durability, and any building or regulatory constraints. Consulting a local expert helps match product selection to your building’s orientation and operational goals.

How Can Window Tinting Improve Employee Productivity?

Window film reduces glare and stabilizes temperatures, creating a more comfortable workspace that supports focus and fewer screen interruptions. Films that retain natural light while filtering UV improve the work environment and can boost employee satisfaction and productivity—an easy retrofit with measurable benefits.

Are There Any Environmental Benefits to Commercial Window Tinting?

Yes. By cutting solar heat gain, window films reduce air-conditioning demand, lower energy use, and help reduce greenhouse-gas emissions. Blocking UV also extends the life of interior finishes and furnishings, reducing replacement waste. Improved energy efficiency is a practical way for businesses to shrink their carbon footprint.

What Maintenance Is Required After Installing Window Film?

Maintenance is simple: clean films with non-abrasive cloths and manufacturer-approved solutions, and avoid ammonia-based cleaners unless explicitly allowed. Periodic inspections for edge lift or damage help catch issues early and protect performance and warranty coverage.

Can Window Film Be Removed or Replaced Easily?

Yes — removal and replacement are routine for professionals, though ease depends on film type and installation quality. Experienced installers use the right tools and techniques to protect the glass. If you plan to replace film, consult a professional to ensure compatibility and avoid complications during removal.

What Are the Warranty Options for Commercial Window Films?

Warranties vary by manufacturer and product. Premium films commonly include material and workmanship coverage ranging from about 5 to 15 years, with some extended options for specific applications. Review warranty terms closely, including maintenance requirements, and ask your installer for clarity on coverage and claim procedures.

How Much Does Commercial Window Tinting Cost in Bend, Oregon?

Cost depends on film performance level (standard solar control vs. high-performance ceramic), total square footage, glazing complexity, and labor conditions like access and staging. Because project variables vary, reputable installers provide measured, itemized quotes after a site survey rather than flat per-square-foot pricing without inspection. Request a professional assessment that documents window types, orientations, and prep work so your quote reflects the true scope and minimizes change orders.

When comparing quotes, focus on film performance metrics (VLT, SHGC, UV block), warranty coverage, and installer workmanship rather than price alone. Accurate quotes help forecast payback timelines based on expected energy savings and operational benefits.

How Long Will Commercial Window Tinting Last and What Maintenance Is Required?

Film life depends on product quality, exposure, and installation quality. Premium commercial films typically perform well for many years when installed correctly and maintained per manufacturer guidelines. Routine care includes cleaning with non-abrasive cloths and approved cleaners, avoiding ammonia-based products when not recommended, and inspecting edges for lift or delamination. Correct product selection for exposure and proper installation are key to achieving the advertised lifespan and maintaining warranty eligibility.

Regular inspections and prompt attention to minor issues maintain optical quality, extend usable life, and protect energy and comfort benefits over time.

Conclusion

Commercial window tinting can deliver meaningful savings, better occupant comfort, and improved privacy for Bend businesses. Understanding the different film types and applications helps decision-makers choose solutions that match operational goals. For tailored recommendations and professional installation, reach out to Alpha Shielding LLC for a consultation — we’ll help you find the right film and a realistic plan to transform your commercial space.

Follow Us

Services

Quick Links

Legal

Copyright Alpha Shielding LLC. All Rights Reserved.